Русский English

Wear tests

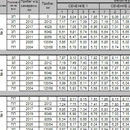

Objective: to determine the tire durability and performance while testing on cars with ballast in the same road conditions, modes and at the same mileage under the following parameters:

- the tread pattern wear of the most wearable part of the tire expressed in millimeters per 1000 km / run.

- mileage of tires up to conditional tread pattern limit of the most wearable part of the tire is determined by the estimated distance – the projected mileage.

- to determine during testing production or operational reasons of tire wearing.

Equipment

- Mitutoyo Electronic depth gauge with a scale of 0.01 mm to measure tread depth.

- Manometer of 1.0 class accuracy to measure air pressure in the tires.

- GPS navigation device to control the route and speed limits.

- Balance platform for distribution of mass between the axles of the vehicle.

- Mannequins for ballast

Test cars in escort at full load perform running on the approved route for 1000 km per day. After 2000 km the tires are inspected and their wear is measured. The tires are interchanged according to the scheme.

For passenger tires the recommended mileage is 12,000 (winter type) and 16,000 km (summer type) with the results provided within 1 month.

Recommended mileage of Truck tires is 120,000–150,000 km depending on the designation of tires with the testing results provided in 3–4 months.